Equipment introduction:

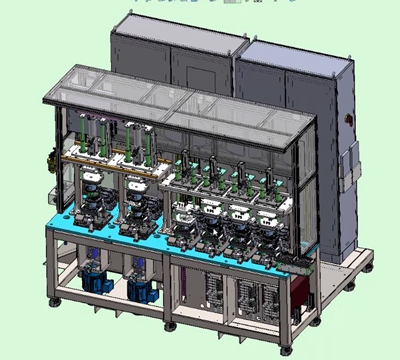

This equipment is a functional testing equipment for electronic power steering motors, consisting of a square steel operating platform, testing fixtures, measuring instrument boards, servo motors, and testing system software;

The operating console is of a pneumatic press bed type structure, equipped with safety gratings and three color alarm lights for safety protection and indication of equipment operation status;

The control of machine IO is completed by the network IO module, with emergency stop and reset buttons installed.

The system software is developed based on the NI LabVIEW platform, with multi station parallel testing, integrating customer MES stop passing functions and data upload functions;

Put the product into the tooling, scan the program for query and tracing, drive the lower drive motor to rotate the product to be tested at a constant speed, complete the collection of product data through CAN communication, calculate the values of BEMF Harmonic, Sensor Harmonic, Calibration, and motor speed through calibration algorithms, and write the calibration values into the product;

The product is placed in the tooling, and the program automatically scans the code and queries for traceability. The product is powered by a programmable DC power supply. The product information and status are detected through a CAN card. The lower load motor rotates at a certain speed, and commands are sent through CAN communication to rotate the product. The torque, voltage, current, and motor speed are collected through a collection card. Torque Blance, CCW&CW Torque, and Fourier Peak to Peak are calculated through a certain algorithm.